\

\

material research: grape pomace and clay mixture, water filtration, grape stems potential

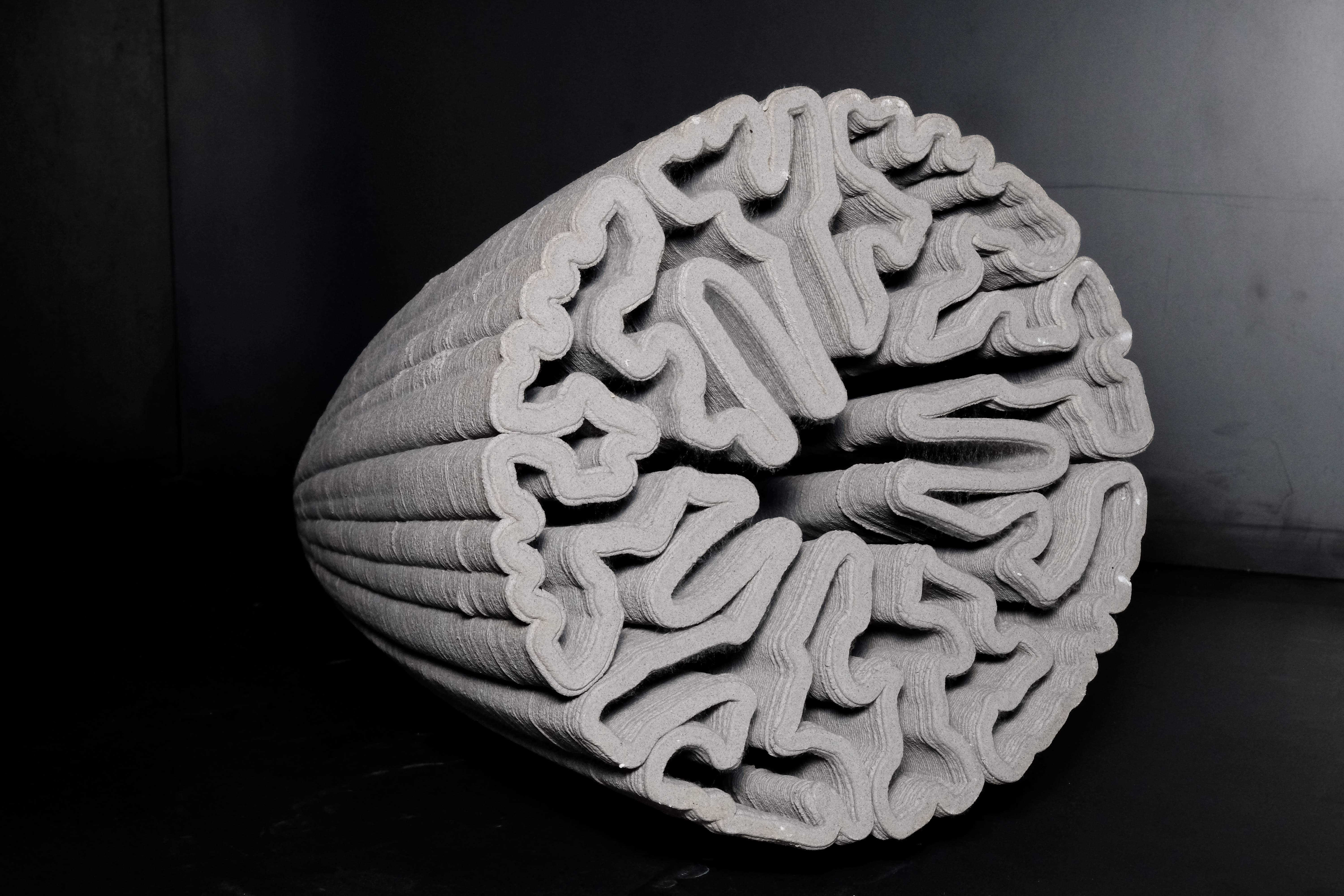

experimentation: 3D clay printing, differential growth, paper making

exhibition: Fondation D'entreprise Martell, Cognac

2023

An experimentation involving the reuse of byproducts from the cognac industry, specifically grape skins and grape stems. For every 1L of eau de vie, approximately 9 kilograms of grape pomace is produced, resulting in tons of biowaste per year. To repurpose the by-products of the cognac industry, experiments were conducted, and two different projects were undertaken during a month-long residency at the Fondation D'entreprise Martel. The first project focused on the combination of grape pomace and clay to create a water filter. The experiments were produced using the unique 3D clay printer developed by engineer and designer Olivier Van Herpt. The second project centered around the experimentation of paper pulp making from grape stems.

Ceramic water filters are created by blending clay with organic material. Traditionally, sawdust, readily available, serves as the organic material of choice. However, in the experiment, powdered grape pomace was chosen instead of sawdust, and the filtration efficiency was evaluated. The filtration results proved to be just as effective as those achieved with sawdust. Throughout the production process, it was observed that the material tended to attract more mold while drying and was slightly less sturdy, although it remained similar to the sawdust mixture in most aspects.

Grapevine paper

For the grape paper-making project, an attempt was made to replicate an experiment conducted two years ago in collaboration with the Krater collective from Ljubljana. The project primarily focused on material preparation and pulp production. After collecting and cleaning grape stems, they were cut, and the cooking process was initiated. The cooked material was then thoroughly cleaned, mixed with water, and subsequently blended. Using paper-making tools, artisanal paper was created. In the end, the results were not as favorable as the initial experiment, but a few successful samples were produced. Some of these samples were placed under a pressing machine, resulting in more condensed paper sheets.